Innovative oyster growout system

I have received several requests for more information on the

Australian Adjustable Longline System (ALS) for oyster growout.

Experienced oyster growers are justifiably fascinated by the

potential of this system.

It was designed, tested and implemented by three oyster growers

from South Australia. It resulted from studying the problems of

the traditional rack and bag system, which is very common in Europe

and some areas of North America.

The primary disadvantage with rack systems on inter tidal zones is

that they allow for a period when the animals are out of the water.

The lack of food and increased stress during low tide contributes

to a slower growth cycle.

To overcome this it makes sense to operate in sub-tidal zones when

using bottom fixed gear. But the problem here is bio-fouling of the

gear and the oysters within.

The primary disadvantage with rack systems on inter tidal zones is

that they allow for a period when the animals are out of the water.

The lack of food and increased stress during low tide contributes

to a slower growth cycle.

To overcome this it makes sense to operate in sub-tidal zones when

using bottom fixed gear. But the problem here is bio-fouling of the

gear and the oysters within.

The innovative solution devised by the South Australian growers is

a longline system that's deployed in the subtidal zone, with 2'

to 4' of water at low tide.

Once you look at all the features of this system, it's easy to see

that Mother Nature is doing about 85 percent of the work.

The innovative solution devised by the South Australian growers is

a longline system that's deployed in the subtidal zone, with 2'

to 4' of water at low tide.

Once you look at all the features of this system, it's easy to see

that Mother Nature is doing about 85 percent of the work.

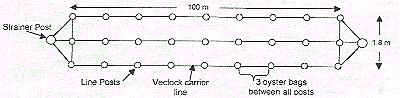

The system is made up of a special Veclock longline to which growout

bags are attached. The longline is supported by a grid of poles which

are fixed in the bottom.

The system is made up of a special Veclock longline to which growout

bags are attached. The longline is supported by a grid of poles which

are fixed in the bottom.

The grid is set up in a design that allows easy access for deployment

and harvest, using specially built flat bottom outboard motor

barges. Two people can install 300 meters of longline in about

six hours.

The grid is set up in a design that allows easy access for deployment

and harvest, using specially built flat bottom outboard motor

barges. Two people can install 300 meters of longline in about

six hours.

Cylindrical open mesh baskets are hung from the longline using

special clips. The growout baskets are able to swing back and forth

freely in any wave action. This swinging motion provides the benefit

of tumbling the oysters. Tumbling causes a pruning effect, which

gives a very symmetrical shape to the animals and helps cup the

shell for the half-shell market.

Cylindrical open mesh baskets are hung from the longline using

special clips. The growout baskets are able to swing back and forth

freely in any wave action. This swinging motion provides the benefit

of tumbling the oysters. Tumbling causes a pruning effect, which

gives a very symmetrical shape to the animals and helps cup the

shell for the half-shell market.

The tumbling action also allows for another benefit. Oysters grown

in protected gear that are constantly in the water column normally

have a thin, more brittle shell that creates problems when the

oyster is opened. To fix the problem, growers using trays or

lantern nets below rafts or longlines have to relay the animals onto

the beach for two to six weeks. There the oysters acclimate and

toughen the shell so they are acceptable to the market. The

problem however, is that this adds extra labour cost.

With the Australian system, the tumbling action replicates the

natural environment of wave action and predation-prone areas,

which causes the animals' shell to toughen - all without extra

labour.

The tumbling action also allows for another benefit. Oysters grown

in protected gear that are constantly in the water column normally

have a thin, more brittle shell that creates problems when the

oyster is opened. To fix the problem, growers using trays or

lantern nets below rafts or longlines have to relay the animals onto

the beach for two to six weeks. There the oysters acclimate and

toughen the shell so they are acceptable to the market. The

problem however, is that this adds extra labour cost.

With the Australian system, the tumbling action replicates the

natural environment of wave action and predation-prone areas,

which causes the animals' shell to toughen - all without extra

labour.

The real plus of the system, though, is spelled out in its name,

Adjustable Longline. Four or five special plastic clips are attached

along the length of each pole of the grid. Thus the placement of

the longline can be raised or lowered depending on your needs.

The real plus of the system, though, is spelled out in its name,

Adjustable Longline. Four or five special plastic clips are attached

along the length of each pole of the grid. Thus the placement of

the longline can be raised or lowered depending on your needs.

With the longline at the bottom clips, the baskets are in the water

all the time at low tide. If it's on one of the middle clips, the

baskets would be at the surface at low tide. And if it's on the

top clip, the baskets are out of the water at low tide. What

this means is that now you have a biofouling control method.

With the longline at the bottom clips, the baskets are in the water

all the time at low tide. If it's on one of the middle clips, the

baskets would be at the surface at low tide. And if it's on the

top clip, the baskets are out of the water at low tide. What

this means is that now you have a biofouling control method.

In the spring of the year (fall in the Southern Hemisphere) when the

water temperature is low and the angle of the sun causes deflection

of direct sunlight off the water, bio fouling is at its least.

You'd use the lowest clips then, so the growout baskets were

always in the water for maximum food availability to the oysters.

In the spring of the year (fall in the Southern Hemisphere) when the

water temperature is low and the angle of the sun causes deflection

of direct sunlight off the water, bio fouling is at its least.

You'd use the lowest clips then, so the growout baskets were

always in the water for maximum food availability to the oysters.

As the summer months approach and the water warms due to the

increased angle of the sun, which causes deeper light penetration,

biofouling increases. By having the baskets in the mid position,

wave action and partial exposure to the sun will help clean the

bio fouling.

As the summer months approach and the water warms due to the

increased angle of the sun, which causes deeper light penetration,

biofouling increases. By having the baskets in the mid position,

wave action and partial exposure to the sun will help clean the

bio fouling.

In the late summer when bio fouling is at its peak, the baskets are

at the top position and out of the water at low tide. Sunlight then

decomposes the biofouling, which is dispersed by wave action during

the rest of the tidal cycle.

In the late summer when bio fouling is at its peak, the baskets are

at the top position and out of the water at low tide. Sunlight then

decomposes the biofouling, which is dispersed by wave action during

the rest of the tidal cycle.

To adjust the longline height takes one hour or less. When you

consider you many have to do this only four to five times during

the growout cycle, that's a very low labour cost.

To adjust the longline height takes one hour or less. When you

consider you many have to do this only four to five times during

the growout cycle, that's a very low labour cost.

Cost Analysis

Seed is put in the baskets after nursery stage or using fine mesh baskets inserts, which allow deployment shortly after hatchery stage. Special plastic wire, which is part of the clip hangers, is also used to hold the folded basket ends closed. This allows for quick and easy loading and unloading of the baskets.

In some locations, existing pier pilings could be used instead of installing the gird of posts. Use of common sense to evaluate the site with respect to water quality and expected output returns.

The average cost of a 300 meter, 300 basket system including locally sourced poles and labour is around $4,000.

If you stock oysters at 150 per basket and you receive an average of 25 cents per oyster, farmgate price, this would produce 300 x 150 x 25 cents or $11,250 gross income. The first cycle gross profit figure is $7,250. Of course, expenses have to be deducted, but you can see the potential for a good net profit too.

With a gear life expectancy of approximately seven to ten years and using an area of a lease that due to labour cost would normally not be used, some growers will find the system a welcome bonus to their operation. The system is currently available for spring delivery from a number of aquaculture suppliers in the US and Canada.

Contact Don Bishop at:

Fukui North America

110-B Bonnechere St.W.

Eganville, Ontario K0J 1T0

CANADA

Email:

don@bishopaquatic.com or call 613-639-3474

Email:

don@bishopaquatic.com or call 613-639-3474

Copyright © 1999-2004 Fukui North America. All rights reserved.